Vinyl Chloride Polymer Thermoplastic Or Thermoset

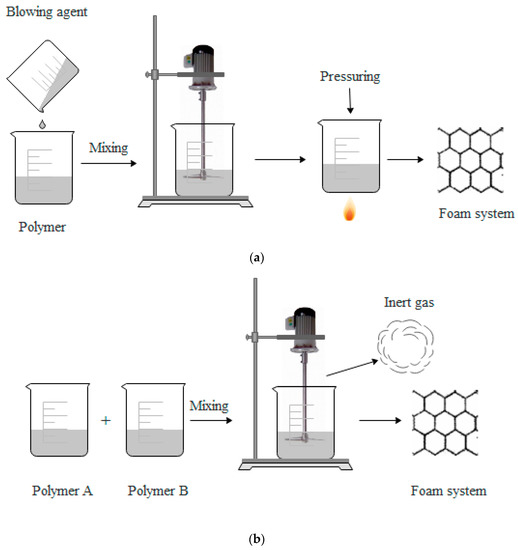

While most polyurethanes are thermosetting polymers that do not melt when heated thermoplastic polyurethanes are also available.

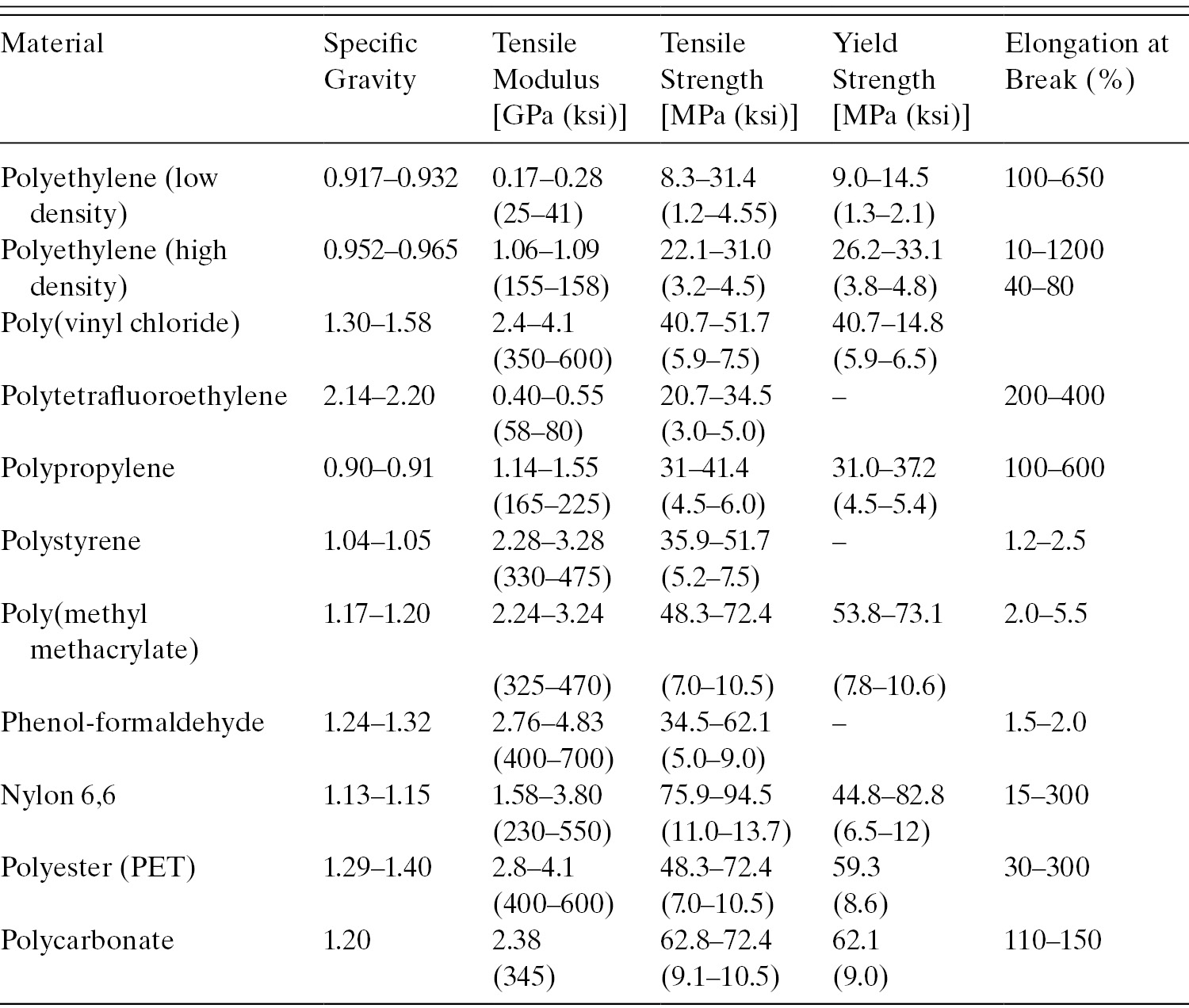

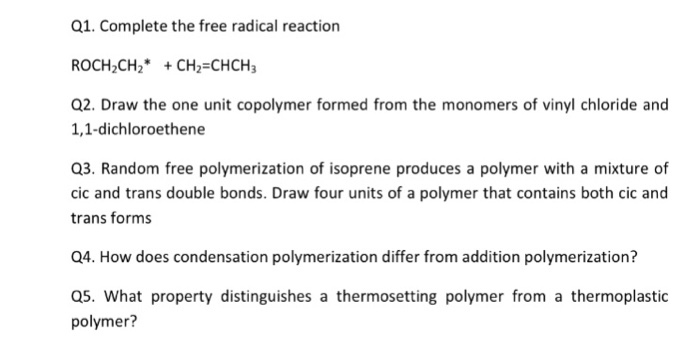

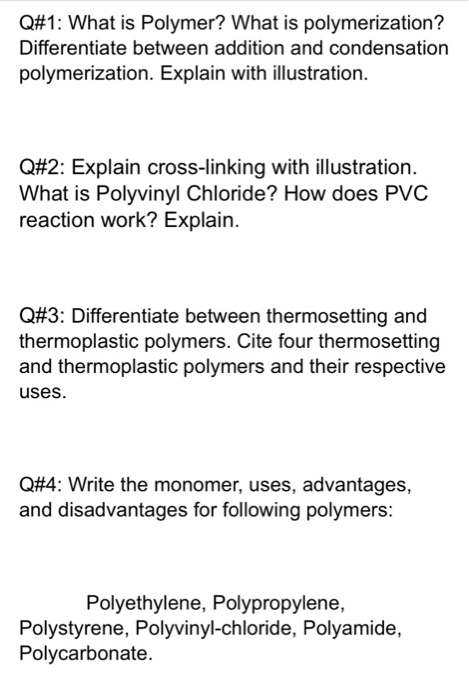

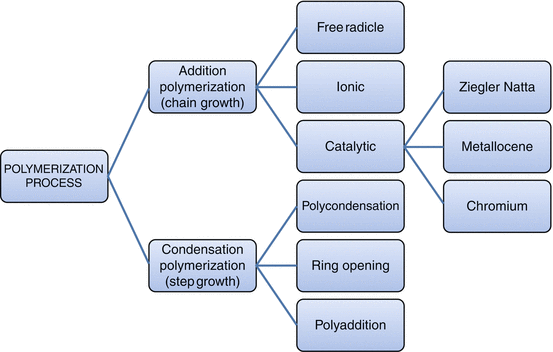

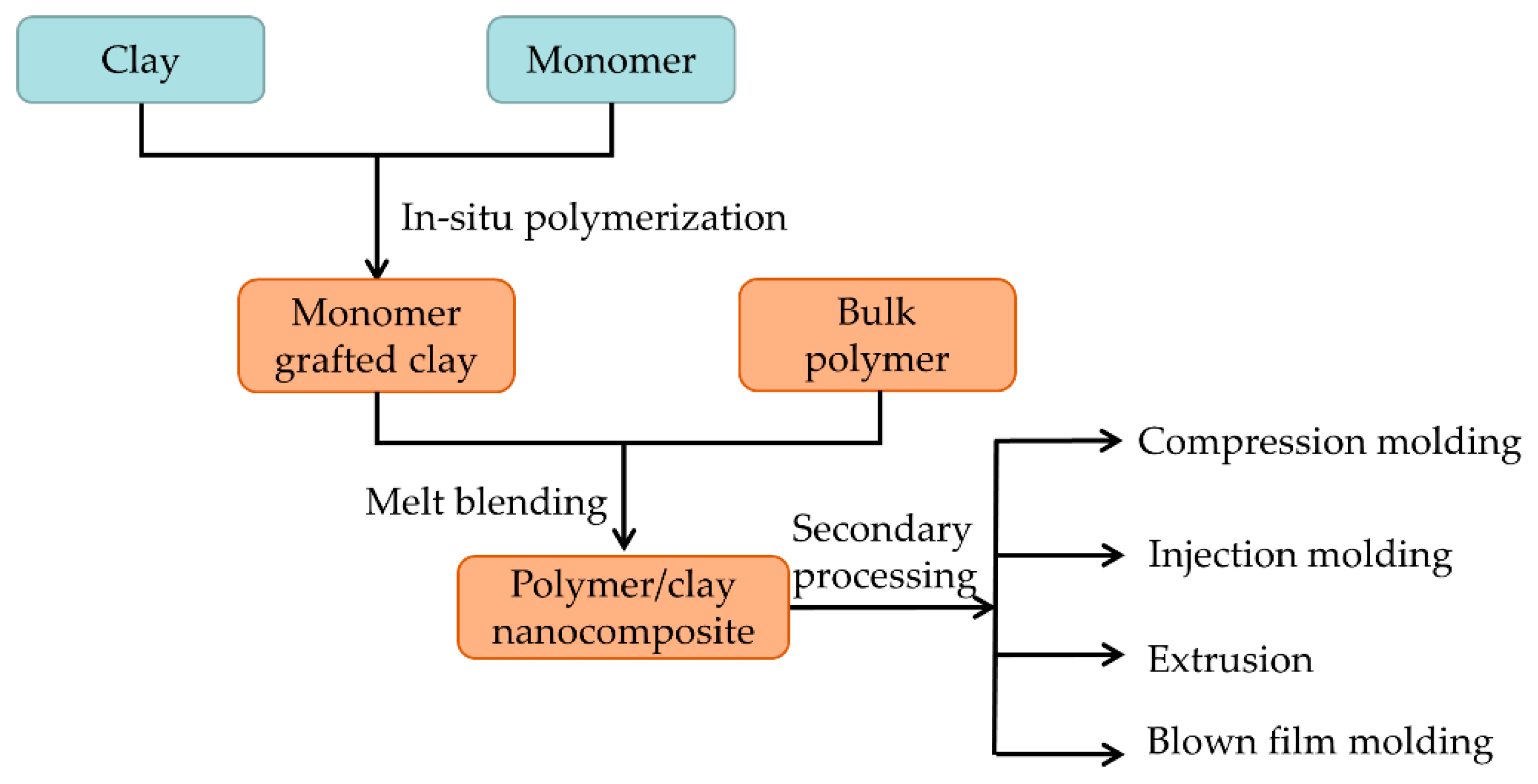

Vinyl chloride polymer thermoplastic or thermoset. It is lightweight and durable and rigid pvc is often used in the construction industry. Based on the flame tests identify which polymers are thermoplastic t. Polyurethane polymers are traditionally and most commonly formed by reacting a di or triisocyanate with a polyol since polyurethanes contain two types of. The thermoplastic material exhibits linear structure i e.

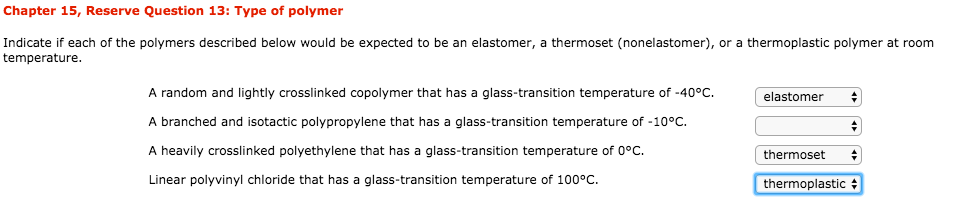

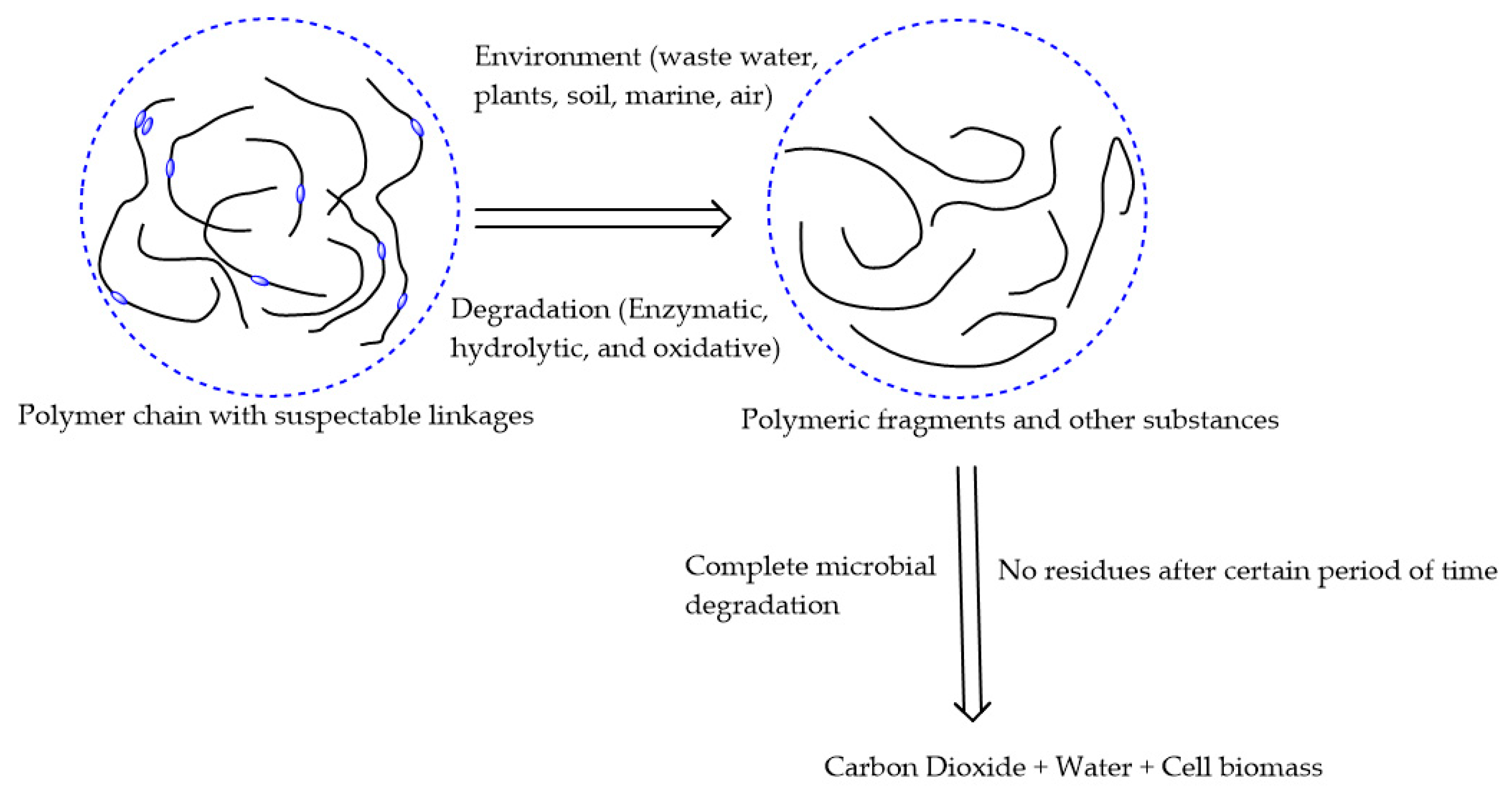

Polyurethane pur and pu is a polymer composed of organic units joined by carbamate urethane links. Poly vinyl chloride pvc teflon. Examples include vinyl siding gutters and drainpipes. A thermosetting polymer also called a thermoset is a polymer that is irreversibly cured of a soft solid or viscous liquid prepolymer or resin.

Pvc is resistant to acids and bases. Ch2 ch2 ch2 ch2 the thermoplastic material is hazardous to the environment which is less when compared to the thermoset and rubber. Thermoplastic and thermoset are terms we use to characterize polymers depending on their behaviour when subjected to heat hence the prefix thermo. A thermoplastic or thermosoftening plastic is a plastic polymer material that becomes pliable or moldable at a certain elevated temperature and solidifies upon cooling.

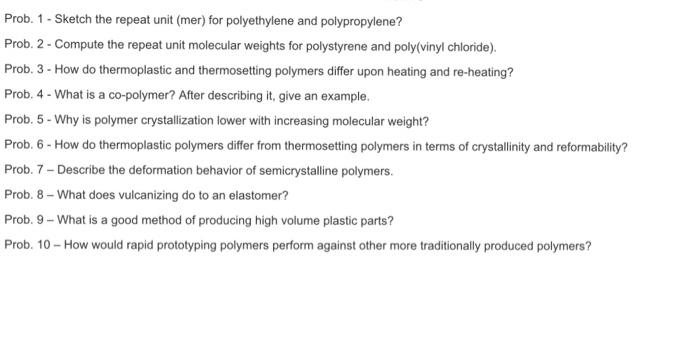

Plastic and which are thermoset t. The process involves using a small quantity of thermoplastic and mixing it with cured thermoset plastic about 70 minimum by weight of all ingredients used under heat and pressure. Most thermoplastics have a high molecular weight the polymer chains associate by intermolecular forces which weaken rapidly with increased temperature yielding a viscous liquid in this state thermoplastics may be reshaped. Thermoplastic pvc is made of 57 chlorine and 43 carbon.

The chlorine is manufactured by the electrolysis of sodium chloride salt and the carbon originates from oil. Polymer particles in a size range between 2 and 15 micrometers and having a refractive index close to but not identical with that of a matrix polymer and optionally having one or more enclosing shells the outer shell being compatible with the matrix polymer impart light diffusing properties to the matrix polymer without degrading its physical properties while the particles having a. The process of curing changes the resin into an infusible insoluble polymer network and is induced by the action of heat or suitable radiation often under high pressure or by mixing with a catalyst. It is not uncommon for people working in polymer businesses e g polymer recycling to ignite a small piece of plastic with a cigarette lighter and identify the polymer based on flame test and odor.

A thermoplastic polymer grafted with functional group is added to create the bonding between the thermoplastic and cured. Its most well known application is the formation of pvc pipes in the building and construction industry but the benefits of pvc extend far beyond this into the medical electrical and protective clothing sectors.